Introduction

If you’ve spent any time scrolling through housing trends or watching futuristic home videos, you’ve probably stumbled across boxable homes and wondered if they’re actually the future—or just clever internet hype. The idea of a fully built house that folds up like a box and ships to your land sounds almost too good to be true.

In reality, housing affordability is becoming a global stress point. Traditional construction is expensive, slow, and filled with uncertainty. That’s exactly why alternatives like boxable homes are getting serious attention from buyers, investors, and even governments.

This topic matters because people aren’t just curious anymore—they’re actively searching for smarter, faster, and more affordable ways to own a home without sacrificing quality or comfort.

Table of Contents

What Are Boxable Homes?

How Boxable Homes Actually Work

Why Boxable Homes Are Gaining Popularity

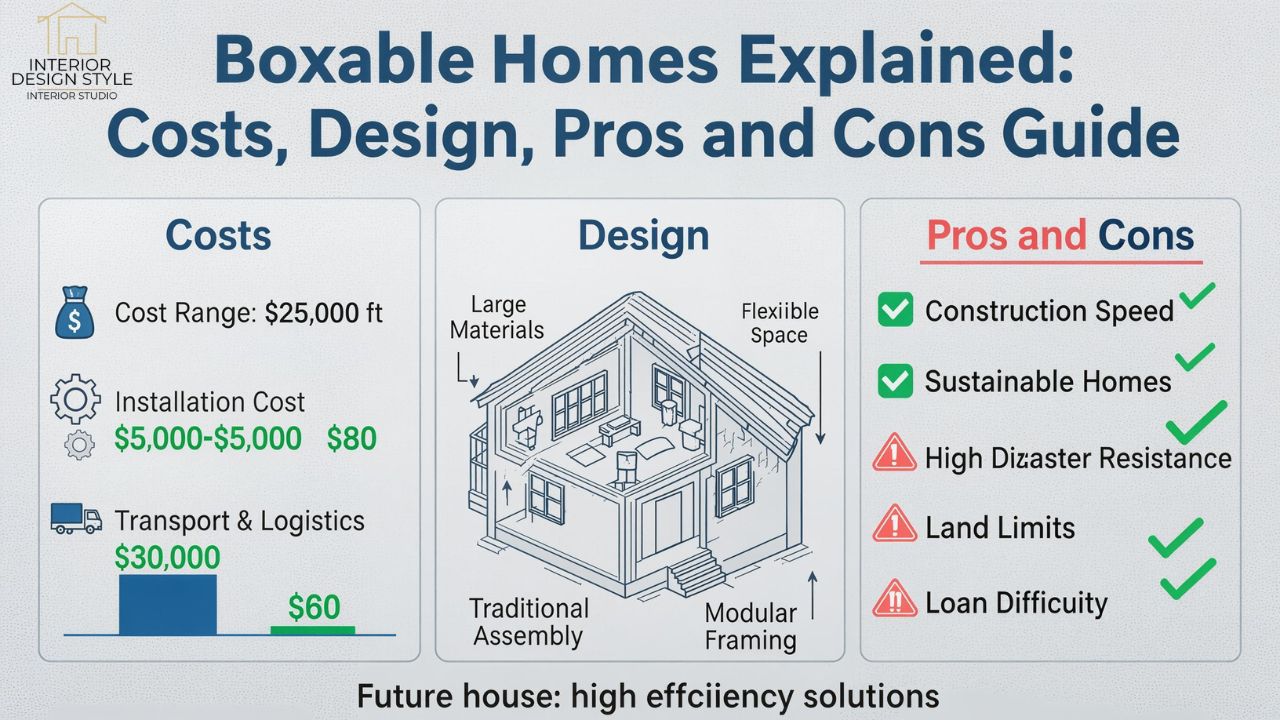

Cost Breakdown: Are Boxable Homes Really Affordable?

Design, Layouts, and Customization Options

Construction Time vs Traditional Homes

Zoning, Permits, and Legal Considerations

Pros and Cons of Boxable Homes

Sustainability and Environmental Impact

Investment Potential and Market Outlook

Personal Background: Who Is Behind Boxable Homes?

Frequently Asked Questions

Conclusion

What Are Boxable Homes?

A simple definition

Boxable homes are prefabricated modular houses designed to fold into a compact box for transport and then expand on-site into a fully functional living space. Unlike traditional modular homes that ship in large sections, these units are engineered to collapse, reducing shipping costs and logistical headaches.

At their core, boxable homes aim to solve three problems at once: high construction costs, long build timelines, and limited housing supply.

How they differ from traditional prefab homes

Traditional prefab homes are built in sections and assembled on-site. Boxable homes, on the other hand, arrive almost fully finished—plumbing, wiring, insulation, and interiors are already installed. Once delivered, the home unfolds, connects to utilities, and becomes livable in days rather than months.

How Boxable Homes Actually Work

From factory to foundation

The process starts in a controlled factory environment. Walls, floors, ceilings, and systems are built with precision machinery rather than exposed job sites. This reduces material waste and weather-related delays.

Once completed, the home folds into a rectangular shipping form that fits on a standard truck.

Installation on-site

After delivery, the unit is placed on a prepared foundation. Hydraulic systems or cranes unfold the structure, locking walls and floors into place. Utility connections are completed, inspections are performed, and the home is ready for occupancy.

Why Boxable Homes Are Gaining Popularity

Housing affordability pressure

In many regions, home prices have outpaced income growth for years. Boxable homes offer a more predictable price point, which is incredibly appealing to first-time buyers.

That said, affordability isn’t just about purchase price—it’s also about speed. Faster builds mean lower financing costs and fewer surprises.

Flexibility and scalability

These homes aren’t limited to individual buyers. Developers see potential for emergency housing, workforce accommodations, student housing, and even luxury modular communities. On the other hand, critics argue scalability still depends heavily on zoning acceptance.

Cost Breakdown: Are Boxable Homes Really Affordable?

Base price vs real-world costs

The advertised base price of many boxable homes often sounds shockingly low. However, real costs include:

- Land purchase or lease

- Foundation work

- Utility hookups

- Permits and inspections

- Transportation fees

- Optional upgrades

When everything is added up, the final price is still often lower than traditional builds, but not as low as viral headlines suggest.

Financing and ownership considerations

Some lenders treat boxable homes like manufactured housing, while others classify them as modular real estate. This distinction affects mortgage terms, resale value, and insurance. In reality, buyers should clarify financing options before committing.

Design, Layouts, and Customization Options

Interior design and livability

Modern boxable homes are designed with efficiency in mind. Open-plan layouts, high ceilings, and integrated storage make smaller footprints feel larger. Kitchens and bathrooms often come fully equipped with modern fixtures.

While customization is possible, it’s usually more limited than custom-built homes.

Expansion and modular add-ons

One interesting feature is modular expansion. Additional units can sometimes be added later, allowing homeowners to scale their living space as needs change. This flexibility appeals to growing families and remote workers alike.

Construction Time vs Traditional Homes

Speed advantage

Traditional homes can take 6–12 months or more from groundbreaking to move-in. Boxable homes significantly reduce this timeline, often completing installation in weeks once permits are approved.

However, permitting delays can still slow things down, especially in areas unfamiliar with modular construction.

Quality control

Factory construction allows for consistent quality checks. Materials are protected from weather damage, and standardized processes reduce human error. That said, quality still depends on manufacturer standards.

Zoning, Permits, and Legal Considerations

Local regulations matter

Not all municipalities welcome boxable homes. Zoning laws may restrict minimum square footage, roof styles, or modular construction altogether.

Before purchasing, buyers should confirm whether local codes allow this housing type.

Utility and inspection requirements

Despite being factory-built, boxable homes must still meet local building codes. Electrical, plumbing, and structural inspections are standard, just like traditional homes.

Pros and Cons of Boxable Homes

Advantages

- Faster construction timelines

- Potentially lower overall cost

- Reduced material waste

- Predictable build quality

- Modern, efficient designs

Drawbacks

- Zoning and permitting challenges

- Limited customization compared to custom builds

- Financing can be complex

- Market resale value still evolving

In short, <strong>boxable homes</strong> offer impressive benefits, but they’re not a universal solution for every buyer or location.

Sustainability and Environmental Impact

Reduced waste and energy efficiency

Factory-built homes generate less construction waste and often include energy-efficient insulation, windows, and HVAC systems. This reduces long-term energy consumption.

However, sustainability also depends on transportation distance and local energy sources.

Long-term environmental considerations

Smaller footprints generally mean lower resource use. Over time, widespread adoption of modular housing could significantly reduce the environmental cost of residential construction.

Investment Potential and Market Outlook

Rental and development opportunities

Investors are increasingly interested in boxable homes for short-term rentals and workforce housing. Faster deployment means quicker returns.

That said, market acceptance is still growing, and resale markets remain less established than traditional housing.

Future growth expectations

As housing shortages intensify, modular solutions are likely to gain regulatory support. Analysts predict steady growth rather than overnight disruption.

Personal Background: Who Is Behind Boxable Homes?

Founders and vision

Boxable was founded with the goal of making high-quality housing faster and more affordable through industrialized construction. The team combines backgrounds in engineering, manufacturing, and real estate.

Their vision focuses on scalability, automation, and cost control rather than luxury branding.

Achievements and financial insights

The company has attracted significant investor interest and media coverage. While exact financial figures aren’t always public, industry estimates suggest strong venture backing and growing production capacity.

Frequently Asked Questions

FAQ

Are boxable homes legal everywhere?

No. Legality depends on local zoning laws and building codes, which vary by city and state.

How long do boxable homes last?

With proper maintenance, they are designed to last as long as traditional homes, often 50 years or more.

Can boxable homes be customized?

Customization is available but typically limited to finishes, layouts, and add-ons rather than full structural changes.

Do boxable homes appreciate in value?

Appreciation depends on location, land ownership, and market acceptance. Trends are still emerging.

Are boxable homes energy efficient?

Most are built with modern insulation and efficient systems, making them competitive with new traditional homes.

Can you get a mortgage for boxable homes?

Yes, but financing terms vary depending on lender classification and local regulations.

How big are typical boxable homes?

Most start as compact units but can be expanded with additional modules.

Are boxable homes safe in extreme weather?

They are engineered to meet building codes, but performance depends on regional standards and installation quality.

Conclusion

Boxable homes aren’t a magic fix for every housing challenge, but they represent a serious shift in how homes can be built, delivered, and owned. For buyers willing to navigate zoning rules and understand true costs, <strong>boxable homes</strong> can offer speed, efficiency, and modern living without the traditional construction chaos. As regulations evolve and acceptance grows, this housing model may move from novelty to mainstream reality.